Overview

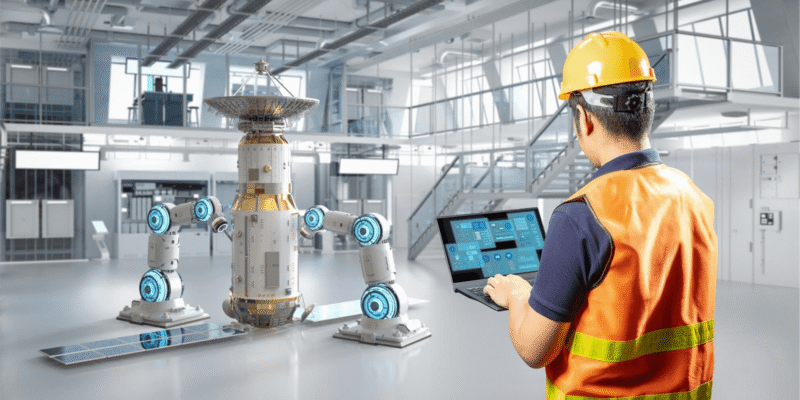

One of our industrial manufacturing partners, operating with a large fleet of heavy machinery across multiple production lines, approached Infysion with a critical challenge: frequent unplanned equipment failures were causing production delays, high repair costs, and operational inefficiencies. Their maintenance approach was largely reactive, with limited visibility into real-time machine health. To solve this, Infysion designed and implemented an AI-powered Predictive Maintenance System that enabled real-time equipment monitoring, early fault detection, and intelligent maintenance planning. The result was a transformation from reactive maintenance to a proactive, data-driven maintenance strategy—significantly improving uptime, productivity, and cost control.

About the Client

The client is a large-scale heavy machinery manufacturer serving industrial customers across multiple sectors. With complex equipment, continuous production cycles, and high maintenance dependency, they required a robust digital system that could monitor machine performance in real time and scale as operations expanded. Their existing maintenance tools were not built for predictive intelligence or centralized visibility, creating gaps in efficiency, reliability, and long-term planning.

Challenges

The client faced several operational challenges that were directly impacting production and profitability.

Unplanned Equipment Downtime

Frequent machine breakdowns were disrupting production schedules and reducing overall equipment efficiency.

Reactive Maintenance Strategy

Maintenance actions were taken only after failures occurred, leading to higher repair costs and extended downtime.

No Real-Time Machine Visibility

Machine health data was not available in real time, making it difficult to identify performance issues early.

Rising Maintenance & Spare Part Costs

Emergency repairs and unplanned spare part usage were driving unpredictable and escalating costs.

Lack of Failure Prediction

There was no intelligence in place to forecast failures based on machine behavior, vibration, or load patterns.

Our Approach

Infysion worked closely with the client’s engineering, IT, and operations teams to design a scalable, intelligent predictive maintenance solution.

Detailed Machinery Health Assessment

We analyzed equipment performance history, breakdown patterns, and critical failure points to define predictive use cases.

IoT Sensor & Data Integration Strategy

We designed an architecture to capture live vibration, temperature, pressure, and operational runtime data from machines.

AI & Predictive Analytics Enablement

Machine learning models were built and trained to detect early warning signals and forecast failures before breakdowns.

Cloud-First Platform Design

A centralized cloud-based platform was created to aggregate, store, and visualize machine health data.

Security & Access Control Framework

Enterprise-grade encryption and role-based access control were embedded into the system.

Phased Implementation & Rollout

The solution was deployed in stages to ensure zero disruption to ongoing production operations.

The Solution

AI-Powered Predictive Maintenance Platform

Infysion delivered a centralized digital platform that provided a unified view of machine health, performance metrics, and risk scores across all connected equipment.

Real-Time Equipment Monitoring

Live sensor data streaming enabled the operations team to monitor machine behavior continuously and identify performance deviations instantly.

Early Failure Prediction & Alerts

The AI engine detected abnormal vibration, temperature, and load patterns and generated early warnings before actual failures occurred.

Automated Maintenance Scheduling

Maintenance activities were automatically triggered based on machine risk scoring—reducing guesswork and manual planning.

Mobile & Web-Based Dashboards

Supervisors and engineers gained secure access to machine data and alerts through real-time dashboards on web and mobile.

ERP & Spare Parts Integration

The system was integrated with inventory and ERP platforms, ensuring spare parts were available exactly when needed.

The Results

The predictive maintenance solution fundamentally transformed how the client managed their production assets. Instead of reacting to breakdowns, the company now proactively manages asset health using real-time data and predictive intelligence. Within months of deployment, the client achieved measurable operational and financial improvements.

Major reduction in unplanned downtime

Significant improvement in equipment reliability & asset lifespan

Faster fault detection & response time

Optimized maintenance scheduling & workforce utilization

Lower maintenance and emergency repair costs

Improved production throughput & operational efficiency

Stronger data-driven decision-making with predictive analytics

Proven Results. Real Impact.

Monitoring and maintaining complex machinery across multiple lines was always a challenge. Since deploying Infysion, we get real-time analytics and predictive alerts that allow our team to act before minor issues become major problems. It’s improved our efficiency, cut maintenance costs, and helped us deliver products on schedule consistently.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.