Overview

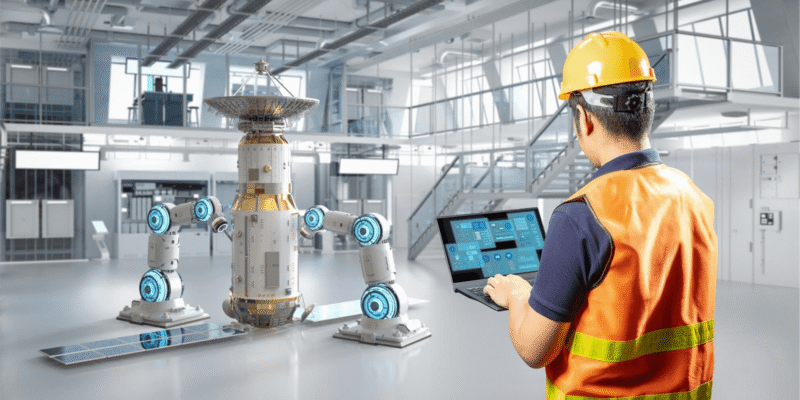

Industrial facilities run on a complex web of utilities—electricity, water, steam, compressed air, chilled water, and fuel systems. Even small inefficiencies in these utilities can significantly impact production costs, sustainability goals, and operational performance. Our client realized that rising energy waste, reactive maintenance, and limited transparency across utility networks were preventing them from achieving peak operational efficiency. To solve this, Infysion designed an Industrial Utility Optimization System that consolidated utility data, automated performance monitoring, and delivered real-time insights into consumption patterns and equipment efficiency. The platform empowered the client to control costs, reduce waste, and optimize industrial utilities with precision.

About the Client

The client is a large industrial manufacturing enterprise operating multiple plants with high utility consumption across steam boilers, chillers, pumps, air compressors, cooling towers, and water treatment units. Their utilities span several zones and departments, all critical to uninterrupted production. As the company scaled operations, the lack of visibility into utility performance, rising operational costs, and regulatory pressure made a modern digital optimization system essential.

Challenges

The client faced several operational challenges that hindered performance and productivity.

Unmonitored Energy Usage Across Utilities

Electricity, steam, and compressed air systems lacked real-time consumption tracking, leading to energy leaks and unnecessary expenses.

Inefficient Water & Process Fluid Management

Water consumption, wastewater discharge, and cooling operations were monitored manually, making optimization difficult.

Inconsistent Equipment Efficiency

Chillers, compressors, boilers, and pumps were running below optimal efficiency with no data-driven insights.

Reactive Maintenance on Critical Utility Assets

Breakdowns occurred without early warning, disrupting production and increasing maintenance costs.

No Centralized Utility Dashboard

Data was scattered across different systems, preventing leadership from making informed decisions.

Our Approach

Infysion collaborated closely with plant operations, energy managers, and utility engineers to develop a scalable digital optimization ecosystem.

Complete Utility Assessment & Data Mapping

We mapped all utility sources—electricity, water, steam, air, cooling systems—to understand consumption, loss points, and inefficiencies.

IoT + Industrial Sensor Integration Strategy

We integrated meters, flow sensors, temperature probes, pressure sensors, and energy analyzers to enable real-time utility monitoring.

AI-Based Optimization & Anomaly Detection

Machine learning models were implemented to detect abnormal consumption, equipment inefficiencies, and utility leaks.

Cloud-Native Industrial Utility Platform

A centralized platform was developed to visualize utility metrics, performance indicators, and multi-plant insights.

Security, Governance & Compliance Controls

Encrypted data flow, access control, and audit trails ensured compliance with environmental and industrial standards.

Phased Deployment Across Plants & Utility Zones

Each utility system was onboarded in phases to ensure smooth transition without production downtime.

The Solution

Centralized Industrial Utility Optimization Dashboard

Real-time visualization of all utilities—electricity, steam, water, compressed air, and cooling systems—across the plant.

Live Monitoring of Utility Consumption & Efficiency

Continuous tracking of load, consumption, and pressure/temperature metrics for critical utility assets.

Anomaly Detection & Performance Alerts

AI models automatically flagged inefficiencies, leakages, abnormal load spikes, and equipment deterioration.

Energy & Water Conservation Optimization

Insights on process waste, recovery potential, and energy-saving opportunities enabled targeted improvements.

Predictive Maintenance for Utility Equipment

Boilers, compressors, chillers, and pumps were monitored for early warning signs to prevent failures.

Role-Based Dashboards for Plant Teams

Operations, energy managers, and leadership accessed tailored dashboards for decision-making and planning.

The Results

The Industrial Utility Optimization System enabled the client to transition from reactive utility operations to intelligent, efficient, and data-driven utility management. Within months of implementation, the client achieved measurable improvements.

Significant reduction in utility consumption & operational costs

Improved equipment efficiency across boilers, chillers & compressors

Faster detection of leaks, losses & abnormal utility usage

Reduced downtime through predictive maintenance

Enhanced sustainability performance & resource conservation

Centralized visibility across all utility systems & zones

Greater scalability for multi-plant industrial operations

Proven Results. Real Impact.

We introduced the utility optimization system mainly to get a better handle on our energy and water usage, but it ended up exposing a lot of inefficiencies we didn’t even realize we had. What impressed me most was how quickly we could tie spikes in consumption back to specific equipment or shifts — something we never had clarity on before. The system has helped us cut waste, improve equipment scheduling, and justify upgrades with hard data instead of gut feel. It’s already paying for itself through reduced utility costs and more predictable operations.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.