Overview

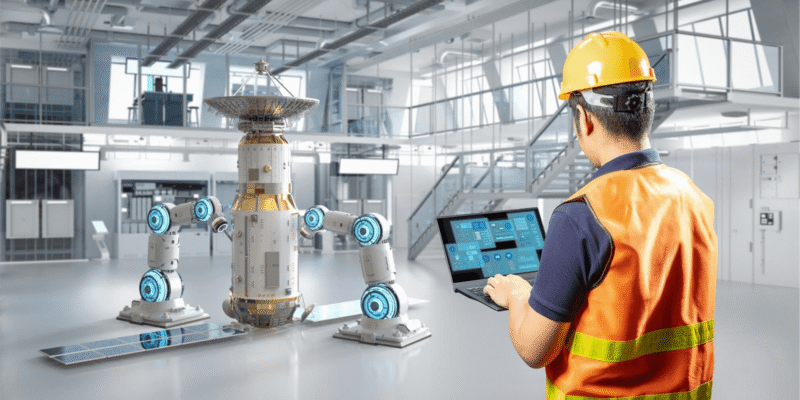

The mining industry is increasingly turning to advanced technologies like IoT and AI agents to streamline operations, enhance safety, and improve profitability. By integrating autonomous fleet management and real-time equipment monitoring, mining companies are able to optimize extraction processes, predict equipment failures, and reduce operational downtime. In this use case, we explore how a South Australia-based client deployed a custom solution leveraging IoT and AI agents to revolutionize their mining operations for smarter extraction and fleet management.

About the Client

The client is a leading provider of wind energy services that manages a large portfolio of wind turbines across Europe and North America. Their goal is to ensure maximum efficiency, reliable performance, and cost-effective solutions for clients involved in the renewable energy sector. With an increasing number of turbines to manage, they needed a platform capable of real-time monitoring, predictive maintenance, and data-driven insights to ensure peak performance.

Challenges

The client’s mining industry customers were struggling with several operational inefficiencies, which were limiting their productivity and increasing operational costs.

Inefficient Fleet Management

Managing large fleets of mining trucks and machinery manually led to inefficiencies in routing, fuel consumption, and maintenance scheduling.

Frequent Equipment Failures

Unplanned downtime and unexpected failures of key mining equipment disrupted operations, resulting in costly repairs and production delays.

Safety Risks

Mining operations, particularly blasting and excavation tasks, posed significant risks to worker safety, requiring constant monitoring and manual intervention.

Data Overload

Although the client was collecting massive amounts of data through IoT sensors, they lacked the tools and systems to effectively analyze and act on this data for better decision-making.

The Solution

To address these challenges, we developed a custom IoT and AI-driven solution tailored to the mining sector, built on Microsoft Azure for scalability and security. This solution integrated autonomous fleet management, real-time equipment monitoring, and predictive maintenance to optimize the entire mining operation.

Autonomous Fleet Management

AI agents autonomously managed the mining trucks and machinery, optimizing routes, fuel consumption, and real-time scheduling. The solution reduced human intervention, improving fleet efficiency.

IoT-Enabled Equipment Monitoring

Real-time data was gathered through IoT sensors attached to mining machinery. These sensors monitored equipment conditions such as vibration, temperature, and fuel levels, sending alerts when problems were detected.

Predictive Maintenance

Using AI agents to analyze the data from IoT sensors, the system could predict when equipment would fail and schedule maintenance before a breakdown occurred, reducing downtime.

Real-Time Data Analytics Dashboard

The solution provided a centralized dashboard that displayed real-time data from various sources. Decision-makers could easily view operational performance, equipment health, and resource extraction efficiency.

The Results

The implementation of this IoT and AI-based solution resulted in significant improvements across the client’s mining operations.

20% reduction in operational costs by optimizing fleet management and extraction processes.

30% improvement in equipment uptime through predictive maintenance, leading to fewer breakdowns and repairs.

40% faster decision-making, thanks to real-time data and AI-powered insights that helped operators make timely, data-driven decisions.

Improved worker safety, as autonomous systems took over high-risk tasks like blasting and excavation, reducing human exposure to dangerous environments.

Enhanced environmental sustainability, as the optimization of resource extraction led to less waste and reduced environmental impact.

Proven Results. Real Impact.

Working with this tech team has completely transformed how we operate. The autonomous fleet management and predictive maintenance have reduced our operational costs, improved equipment uptime, and most importantly, enhanced the safety of our workforce. Our decision-making is now more data-driven and efficient, and we are already seeing significant ROI. We’re proud to help mining companies operate smarter and safer with our cutting-edge solutions.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.