Overview

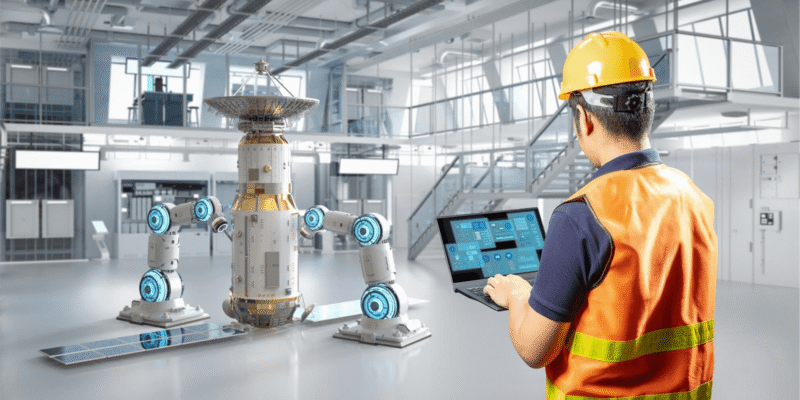

Oil & Gas operations depend on precision, uptime, and safety—yet vast distances, aging infrastructure, and extreme operating conditions make real-time visibility incredibly difficult. Our client, responsible for managing critical assets across pipelines, wellheads, compressors, and refinery units, relied heavily on manual inspections and disconnected SCADA dashboards. This approach led to delayed fault detection, unplanned shutdowns, and escalating maintenance costs.To overcome these challenges, Infysion developed an Industrial IoT & Digital Twin Platform tailored for Oil & Gas environments. The solution created real-time digital replicas of critical assets and field operations, enabling predictive maintenance, performance simulation, and safer, data-driven decision-making across the entire value chain.

About the Client

The client is a regional Oil & Gas operator overseeing upstream field assets, midstream pipeline infrastructure, and downstream processing units. Their operations include:

- Wellhead equipment

- Pumps & compressors

- Storage tanks

- Pipeline grids

- Refinery processing units

- On-field mechanical assets

Their existing monitoring tools lacked centralized visibility, making it difficult to detect failures early, measure asset health, or coordinate maintenance across geographically dispersed sites.

Challenges

The Oil & Gas environment presented several complex operational challenges.

Fragmented Monitoring Across Wells, Pipelines & Plants

Each site operated independently with SCADA-driven data silos and inconsistent reporting formats.

High-Risk Equipment Failures

Compressor overheating, pump vibration anomalies, pressure deviations, and flow interruptions often went undetected until system failures occurred.

Manual Field Inspections & Delayed Fault Response

Critical assets required on-ground inspections, increasing response time and operational risks.

Safety & Compliance Requirements

Regulatory demands for traceability, safety logs, environmental data, and incident reporting were difficult to meet manually.

Lack of Predictive Insights

The client could not forecast failures or simulate operational scenarios using existing tools.

Our Approach

Infysion collaborated with the operator’s SCADA teams, field engineers, refinery supervisors, and operations leadership to build a fully integrated IoT & Digital Twin ecosystem.

Operational Asset & Process Mapping

We analyzed upstream, midstream, and downstream workflows to understand data gaps, equipment dependencies, and risk zones.

IoT Sensor Integration Across Remote Assets

Integrated pressure, temperature, vibration, flow, acoustic, and gas detection sensors via gateways and industrial protocols (Modbus, OPC-UA).

Digital Twin Models for Critical Assets

Created virtual replicas for wellheads, compressors, pumps, and critical refinery units based on real-time machine behavior and historical patterns.

Predictive Maintenance Algorithms

Built ML models detecting early signs of degradation, leaks, vibration abnormalities, fluid imbalance, and impending equipment failure.

Cloud-Based Oil & Gas Monitoring Platform

Centralized data from SCADA, sensors, and PLCs into one secure, real-time operations dashboard.

Security, Compliance & Audit Framework

Implemented access control, encryption, safety logs, environmental compliance reports, and forensic traceability.

Phased Implementation Across Production Fields

Rolled out the solution site-by-site to ensure operational continuity and staff adoption.

The Solution

Real-Time Visibility Across the Oil & Gas Network

Unified view of operational health across wells, pipelines, compressors, and refinery equipment.

Digital Twins for Critical Machinery & Field Assets

Virtual replicas modeled actual operating behavior to predict failures before they occurred.

Intelligent Fault Detection & Incident Alerts

Detects vibration anomalies, pressure deviations, overheating risks, flow disruptions, and potential leak points.

Predictive Maintenance Scheduling

Automatically recommends maintenance actions based on condition, not calendar cycles—reducing downtime and emergency repairs.

Pipeline Performance & Leak Simulation

Digital twins helped simulate pressure loss scenarios, enabling earlier detection of possible leaks or flow blockages.

Mobile App for Field Engineers

Engineers received alerts, diagnostics, and equipment reports directly on mobile devices, enabling faster response.

Operational Analytics & Compliance Dashboards

Real-time insights into energy usage, environmental compliance, asset utilization, equipment reliability, and safety trends.

The Results

The Industrial IoT & Digital Twin Platform elevated the operator’s asset reliability, safety, and operational efficiency across their Oil & Gas network. After deployment, the client experienced significant improvements.

Reduced unexpected failures of pumps, compressors & wellhead assets

Lower maintenance costs through condition-based interventions

Faster detection of pressure anomalies, leaks & flow disruptions

Enhanced pipeline & equipment safety compliance

Improved uptime & throughput across drilling & processing operations

Centralized visibility over remote field assets

Scalable foundation for enterprise-wide Industry 4.0 adoption in Oil & Gas

Proven Results. Real Impact.

We needed a way to monitor equipment health and optimize production without constantly sending teams to remote locations. With Infysion, we can track critical assets in real time and leverage digital twins to simulate performance under different conditions. It’s helped us prevent costly failures, make faster decisions, and increase overall asset reliability.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.