Overview

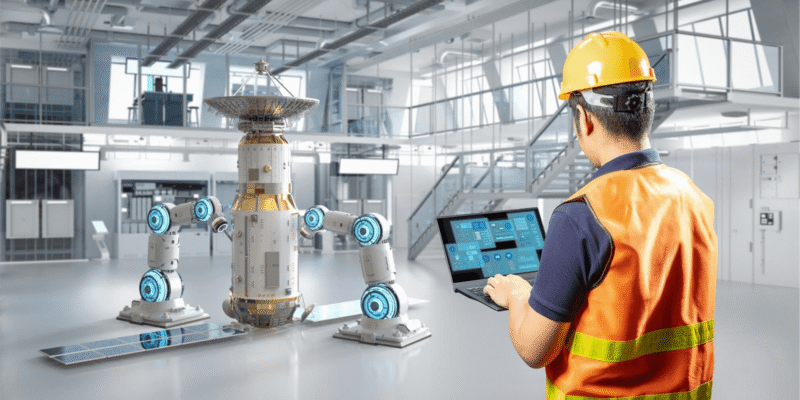

Cold-chain logistics demands precision. Even a small temperature deviation can spoil inventory, increase losses, and damage client trust. Our client—responsible for transporting temperature-sensitive products such as pharmaceuticals, frozen foods, and specialty perishables—noticed that their cold-chain operations lacked real-time visibility and proactive control. Drivers manually logged temperature readings, alerts often came too late, and delivery timelines were affected by manual coordination. To eliminate these inefficiencies, Infysion built a Smart Cold-Chain Delivery Platform, enabling real-time temperature tracking, intelligent routing, automated alerts, and end-to-end visibility across the cold-chain network. The system empowered the client to maintain product integrity, prevent spoilage, and deliver consistent cold-chain performance at scale.

About the Client

The client is a logistics service provider specializing in temperature-controlled transportation for food distributors, pharmaceutical companies, and retail suppliers. Their fleet includes refrigerated trucks, cold-storage vans, and multi-zone temperature vehicles operating across long-haul and last-mile delivery routes. As demand increased, maintaining strict temperature control and ensuring compliance across all shipments became operationally challenging without a centralized digital platform.

Challenges

The client faced several cold-chain operational challenges that directly impacted quality and delivery performance.

No Real-Time Temperature Visibility

Temperature readings were logged manually, resulting in delayed detection of fluctuations inside cold compartments.

Inefficient Route Planning for Perishable Goods

Routes were not optimized based on product sensitivity, delivery priority, or traffic conditions.

Delayed Detection of Cold-Chain Failures

Door openings, equipment malfunctions, and cooling unit issues went unnoticed until after spoilage occurred.

Compliance & Audit Limitations

Maintaining FDA, HACCP, or FSSAI compliance required detailed logs and traceability, which were difficult to generate manually.

Limited Shipment-Level Traceability

Operations teams could not track the exact condition of goods across different legs of the journey.

Our Approach

Infysion worked closely with fleet managers, logistics coordinators, and cold-chain specialists to engineer a robust, data-driven cold-chain platform.

Cold-Chain Workflow & Risk Assessment

We analyzed fleet operations, temperature-sensitive SKUs, loading workflows, and compliance requirements.

IoT Sensor & Reefer Unit Integration Strategy

Sensors for temperature, humidity, door activity, GPS, and vibration were seamlessly integrated with reefer units.

AI-Powered Spoilage Prediction Models

Machine learning algorithms were developed to detect abnormal patterns and forecast potential cold-chain failures.

Cloud-Native Delivery Platform Architecture

A centralized system was built to manage shipments, fleet, temperature control, and compliance logs across locations.

Secure Access, Data Governance & Compliance Controls

Encrypted communication, digital audit trails, and compliance-based data retention were embedded into the platform.

Phased Rollout Across Long-Haul & Last-Mile Routes

The solution was implemented across vehicle clusters to ensure smooth adoption without disrupting operations.

The Solution

Real-Time Temperature & Condition Monitoring

Continuous monitoring of temperature, humidity, door openings, and overall compartment conditions, with instant alerts for deviations.

Smart Route Optimization for Perishables

AI-driven routing prioritized delivery timelines based on product sensitivity, traffic data, and cooling efficiency requirements.

Automated Cold-Chain Alerts & Incident Management

The system triggered alerts for temperature spikes, door breaches, equipment failures, and route delays.

Reefer Unit Diagnostics & Predictive Insights

Cooling units were monitored for performance degradation, enabling early maintenance intervention.

Mobile App for Drivers & Delivery Staff

Drivers received real-time route updates, temperature alerts, and digital delivery instructions.

Digital Compliance & Traceability Logs

Automated, audit-ready logs tracked each shipment’s temperature history, route conditions, and handling activities.

The Results

The Smart Cold-Chain Delivery Platform enabled the client to transform their cold-chain operations from manual and reactive to fully automated, intelligent, and compliant. Within months of deployment, the client experienced measurable improvements

Significant reduction in product spoilage & temperature-related losses

Improved delivery reliability & SLA performance

Enhanced route efficiency & reduced fuel consumption

Faster incident response to cold-chain failures

Stronger regulatory compliance & ready-to-export documentation

Full traceability across long-haul & last-mile delivery stages

Greater fleet scalability & operational control

Proven Results. Real Impact.

Our clients rely on precise temperature control for their sensitive products, but we struggled with visibility across multiple carriers. Infysion gave us end-to-end tracking and automated reporting, making it easy to ensure compliance and maintain trust. Delivery performance and client satisfaction have improved dramatically.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.