Overview

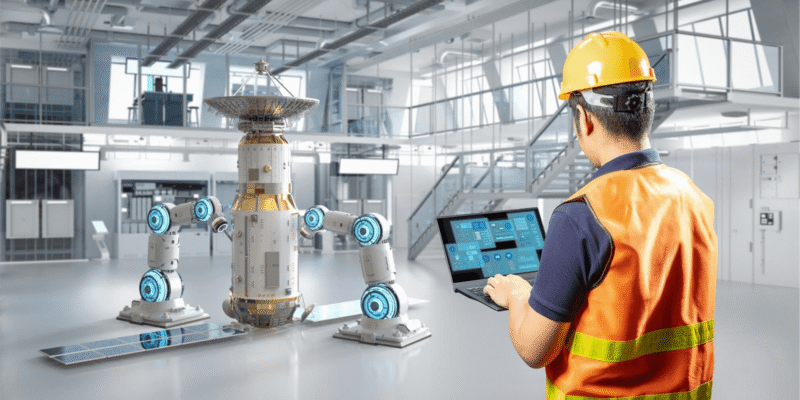

In modern warehousing, speed, accuracy, and real-time coordination define competitiveness. Our client—a growing distribution and fulfillment operator—recognized that their warehouse operations were still heavily dependent on manual picking, paper-based tracking, and fragmented systems. Inventory discrepancies, slow order fulfillment, and limited visibility were holding back their ability to scale. To overcome these constraints, Infysion developed a Smart Warehouse Automation System that unified inventory control, automated warehouse workflows, and enabled real-time operational intelligence. The platform transformed their warehouse into a highly coordinated, data-driven environment capable of supporting higher volumes with greater accuracy and efficiency.

About the Client

The client is a mid-sized warehousing and distribution company managing multiple storage facilities for retail, FMCG, and ecommerce partners. Their operations involve high SKUs, fast-moving inventory, and strict SLA-driven fulfillment requirements. As they expanded their fulfillment partnerships, they needed a scalable digital solution that could automate warehouse processes and remove dependency on manual operations.

Challenges

The client faced several warehouse inefficiencies impacting turnaround time, accuracy, and scalability.

Manual Inventory Tracking & High Error Rates

Stock counts were maintained manually, leading to frequent discrepancies between physical and system inventory.

Slow Picking, Packing & Dispatch Workflows

Disconnected tools and lack of guided workflows slowed down order processing during peak volumes.

Limited Real-Time Visibility Across Warehouse Zones

Supervisors had no live insight into inventory locations, workforce progress, or order status.

Poor Space Utilization & Storage Planning

Without intelligent insights, racks, bins, and zones were not optimized for SKU velocity or size.

No Predictive Insights for Demand or Stock-Outs

The warehouse relied on reactive decision-making instead of forecasting and proactive planning.

Our Approach

Infysion partnered with the client’s operations, warehouse supervisors, and IT teams to design a modern, automated warehouse ecosystem.

In-Depth Warehouse Workflow & Layout Analysis

We mapped the full lifecycle—from inbound receiving to outbound dispatch—to identify automation opportunities.

IoT, Scanning & Sensor Integration Strategy

RFID tags, barcode systems, handheld scanners, and zone sensors were integrated to enable real-time tracking.

AI-Based Optimization Models

Algorithms were implemented for intelligent slotting, picking sequence optimization, and demand forecasting.

Cloud-Native Warehouse Platform Architecture

A centralized warehouse management platform (WMS) was built using cloud scalability and multi-location support.

Role-Based Access & Security Compliance

Different warehouse roles—pickers, packers, loaders, supervisors—were given secure role-based access.

Phased Automation Deployment

Automation was implemented in stages to minimize workflow disruptions and ensure easy staff adoption.

The Solution

Centralized Warehouse Automation Platform

A unified system managing inventory, workers, equipment, and orders across zones and facilities.

Real-Time Inventory Tracking & Smart Slotting

Automated stock updates and AI-driven storage recommendations improved accuracy and space utilization.

Automated Picking & Packing Workflows

Guided picking routes, scan-based confirmation, and workstation optimization increased processing speed.

IoT-Enabled Warehouse Visibility

Live insights into item movement, worker productivity, and zone congestion enhanced operational control.

Optimized Order Fulfillment & Dispatch Coordination

Orders were auto-prioritized based on SLA, volume, and delivery schedules.

Mobile & Web Dashboards for Supervisors

Managers gained real-time oversight of inventory, workforce performance, and operational bottlenecks.

The Results

The Smart Warehouse Automation System enabled the client to move from manual, labor-intensive operations to a streamlined, intelligent, and scalable warehouse ecosystem. Within months of deployment, the client achieved measurable improvements.

Major reduction in inventory discrepancies & stock errors

Increased order fulfillment speed & accuracy

Improved worker productivity through guided workflows

Enhanced real-time visibility across warehouse zones

More efficient space utilization & storage planning

Reduced operational costs & manual workloads

Greater scalability for new SKUs, partners & facilities

Proven Results. Real Impact.

Our warehouses were operating at full capacity, but inefficiencies in inventory tracking and picking workflows limited performance. Infysion’s Smart Warehouse Automation System provides real-time inventory updates, AI-driven storage recommendations, and automated picking and packing workflows. IoT sensors give live insights into worker productivity and zone congestion, enabling proactive management. The result is faster order fulfillment, reduced errors, and more efficient use of space.

Optimize Your Environment with Smart Solutions

Discover how smart technologies can transform your spaces for better safety, efficiency, and sustainability. Learn more!

REACH OUT NOW!

+1 (866) 422-6603

Start the collaboration with us while figuring out the best solution based on your needs.